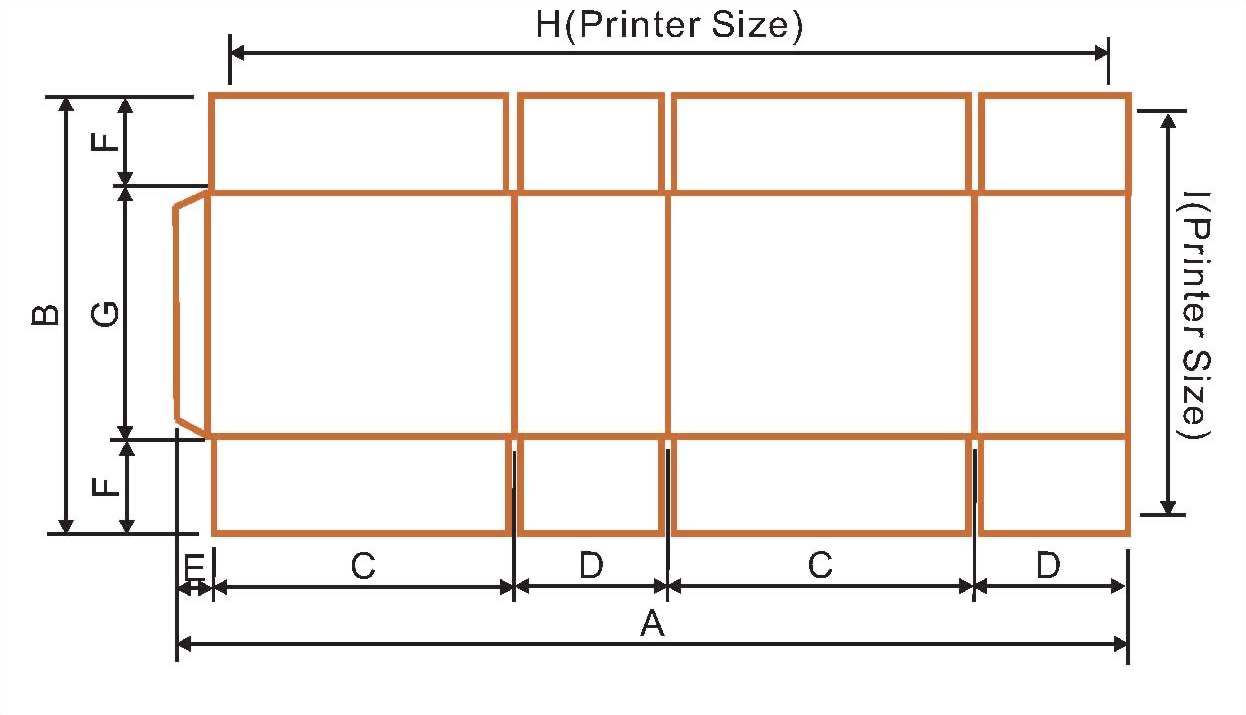

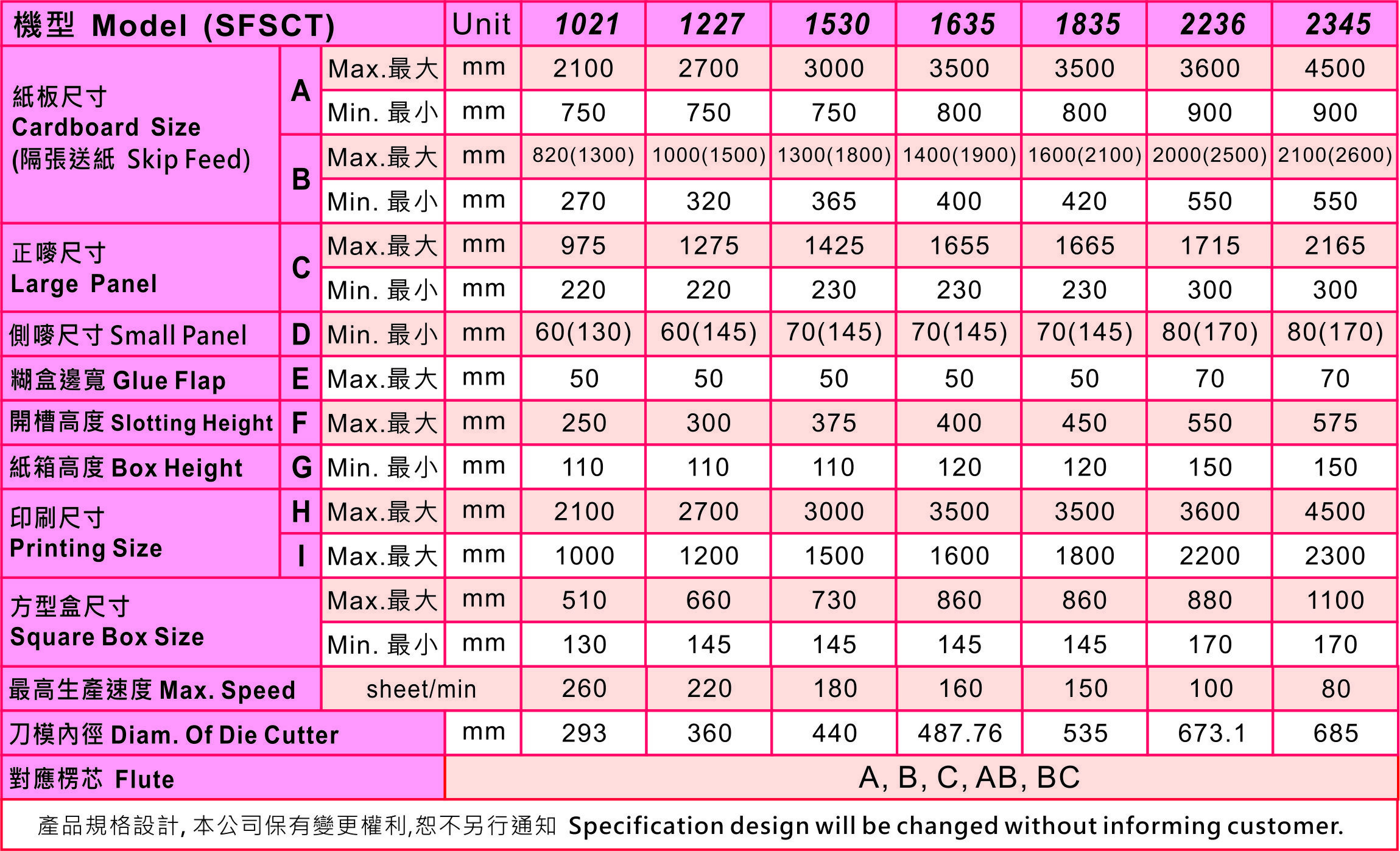

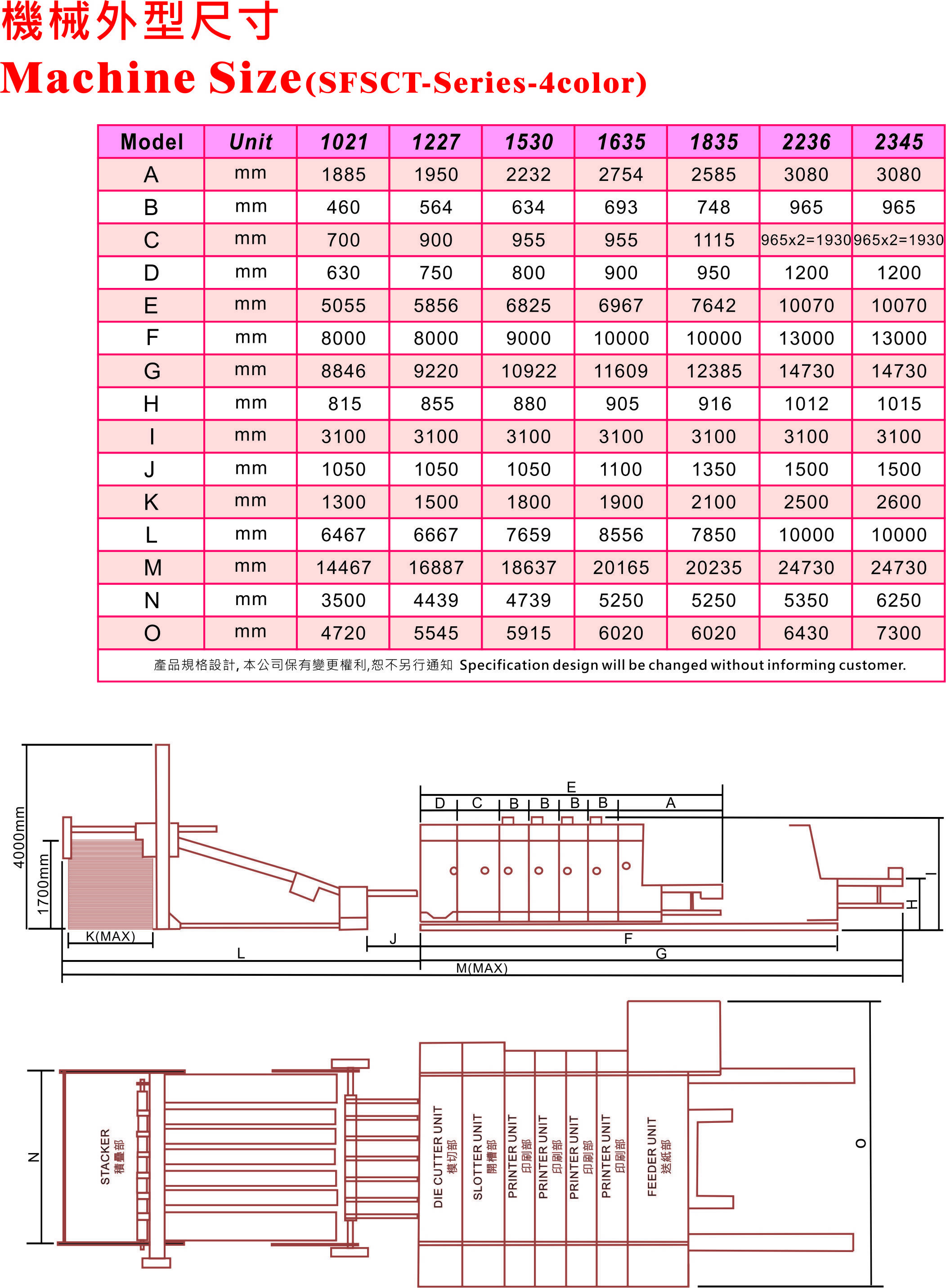

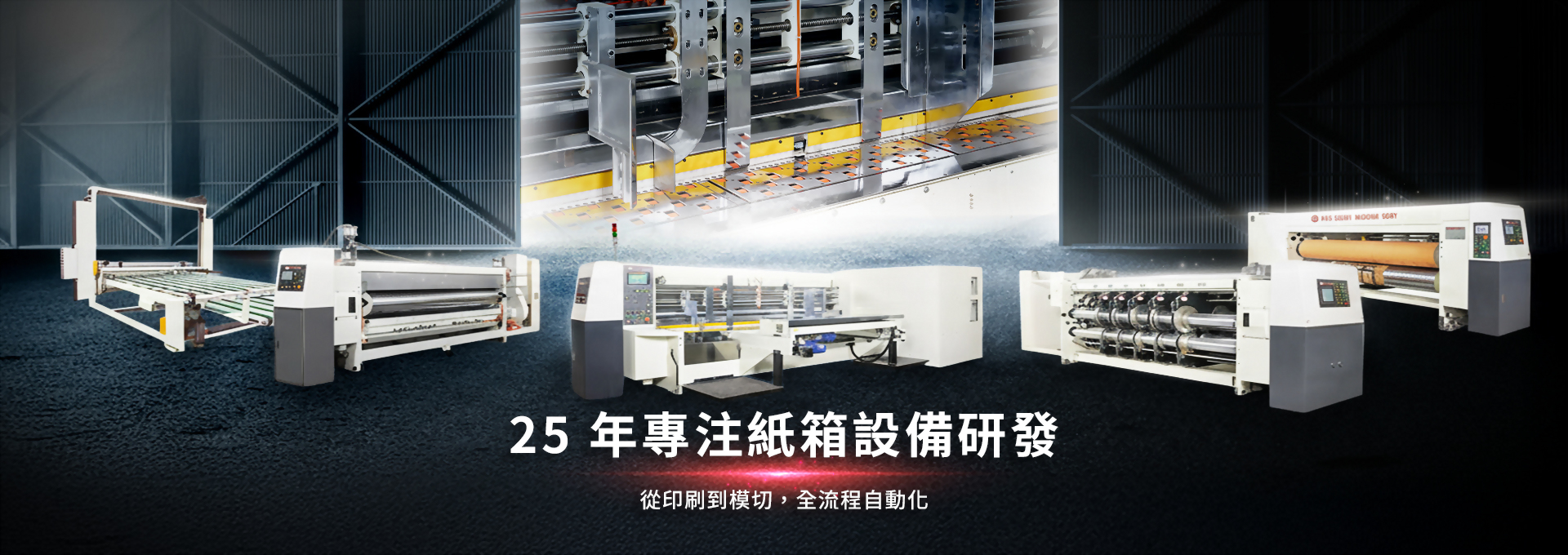

FLEXO PRINTER (NC)

Lead edge feeder unit

-

YASKAWA server motor control system to enable, high speed and accuracy during

feeding of cardboard. -

Automatic Slip Compensate system is when machine on difference speed can to

accurate position of feeding . -

Effective in getting together the machine and electricity and effective to handle position、

speed and acceleration. - With a pneumatic skip feed device in order to produce larger size boxes.

-

The cardboard-supporter、side guides can automatically move to the preset position by

HMI system.

Dust Collection Unit (Optional) :

-

Electric brush system can effective in getting rid of dust and paper powder on the

cardboard. - Electrostatic precipitator system .

Printer Unit :

- Top printer.

- Laser engraved ceramic anilox rolls.

- Made of A-class seamless pipe coated with a special wear-resistant and oil-proof black NBR .

-

Integrated pneumatic ink pump、filter and ink cycling system for high-precision printing, also

for protecting the anilox roll and the rubber roll. -

Printer unit is complete with an auto positioning and electric adjustment, this function would

allow operator’s to position the printing drum back to printing position. - All of the roller with dynamically balanced.

Optional :

-

Vacuum transfer system is equip with durable tungsten carbide guide wheels.

This system greatly improve the printing accuracy and would overcome warp boards issues. -

Doctor blade “ Chamber” type would be suggested for high quality printing,

hence this would also be a cost saving on the ink material.

Slotter Unit :

- Adopting single shaft design for slotting knife.

- Slotting knife base lateral movement by ballscrew and linear guideway for smoothly moved.

-

Crease bearing bed and slotting knife bearing bed simultaneously co-adjusted for keeping

cutting accuracy and avoiding slotting knife worn away. -

The distance adjustment of slotting knife base motorized by auto positioning equipped with

the scale on a ruler, also by manual micro-tuning. -

Manual adjustment with display for the gap control of the bottom slotting wheel shaft and bottom

pre-creasing wheel shaft and bottom creasing wheel shaft. - 5 units of moveable slotter knives that allow full open and close options.

Optional : Dual slotter unit

Die Cutter Unit :

- The auto gap control of cutting mould will prolonging the life spend of the die cut anvil.

- The anvil roll is design with side notion movement to enable different depression area on the anvil.

- Auto-searching die cutter position with auto-zero function.

-

Speed compensation device system allow operator’s to adjust the speed ratio between anvil and

die mould cylinders.

Stacker :

- The stacker conveyor belt speed is complete with 2 option

1) Link-up (interface) with FLEXO speed.

2) Independent speed adjustment cording operator’s requirement.

- Equipped with prevent fall safety design prevents outrigger dropping.

- Stacker end would be complete with “Hydraulic Neat Stack” devise for finish carton.

SCROLL DOWN

SCROLL DOWN